Live Updates

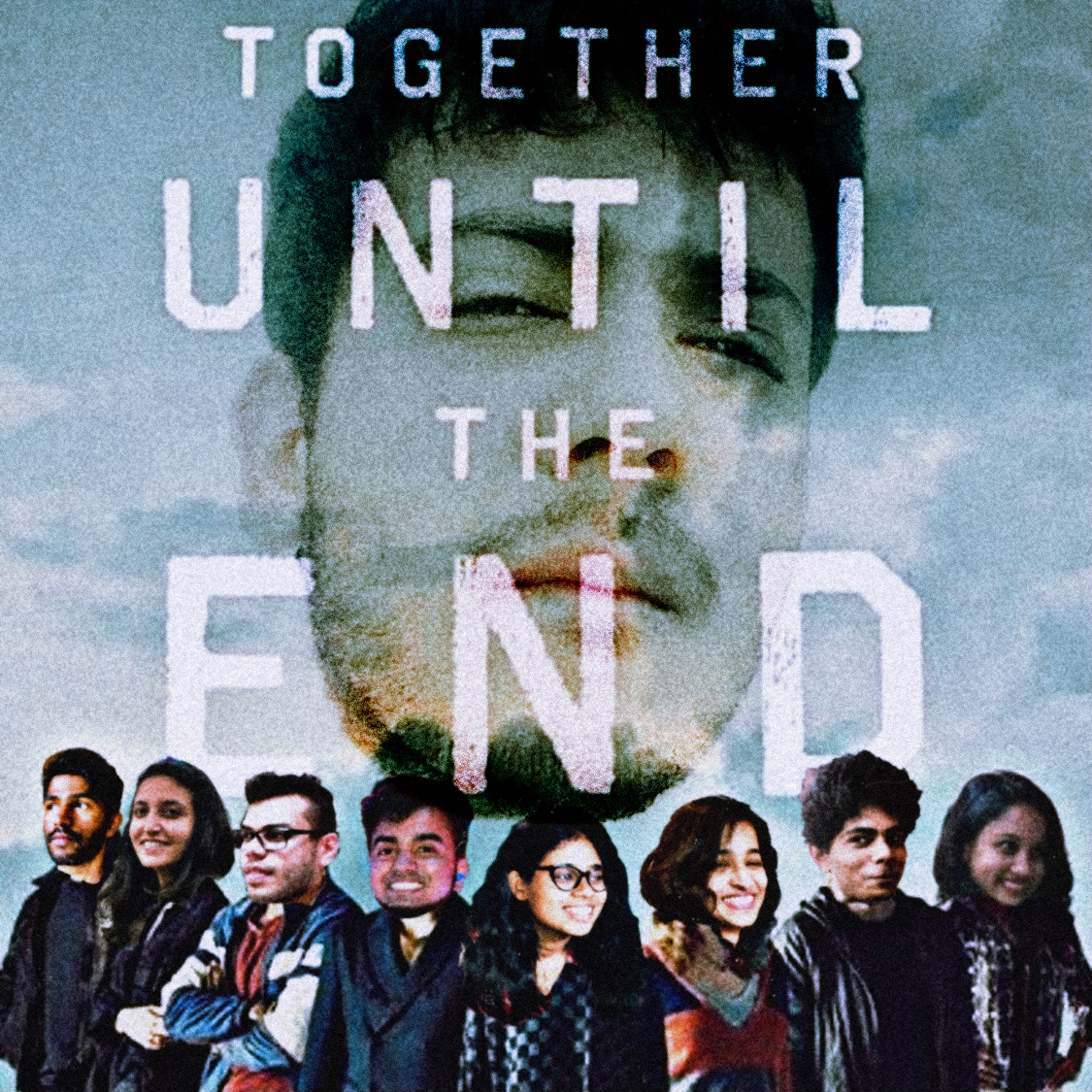

Atharv

Active Days:

Rest Days:

Anjali

Active Days:

Rest Days:

Donovan

Active Days:

Rest Days:

Malaika

Active Days:

Rest Days:

Rohit

Active Days:

Rest Days:

Reuben

Active Days:

Rest Days:

Charlene

Active Days:

Rest Days:

Dwayne

Active Days:

Rest Days: